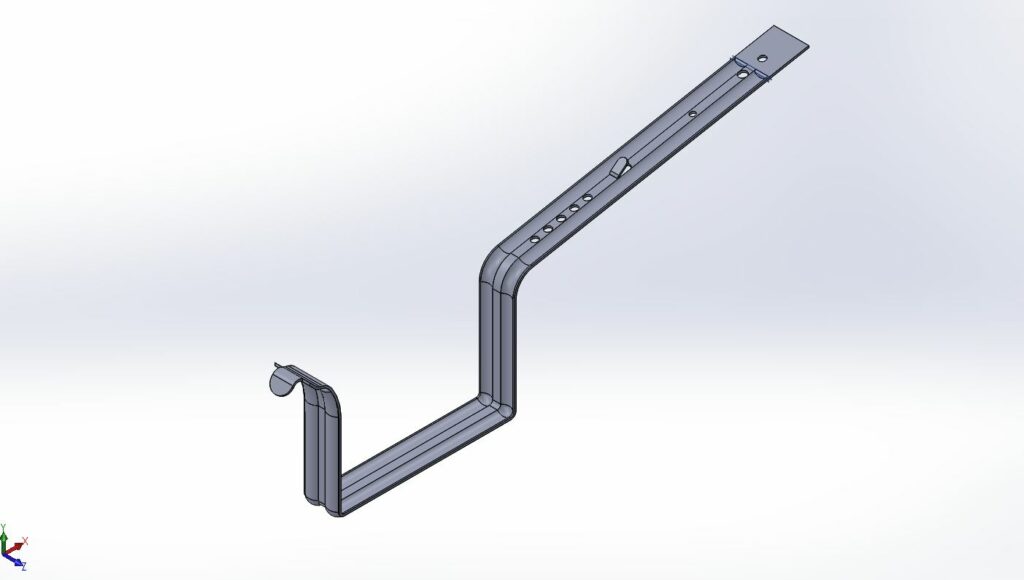

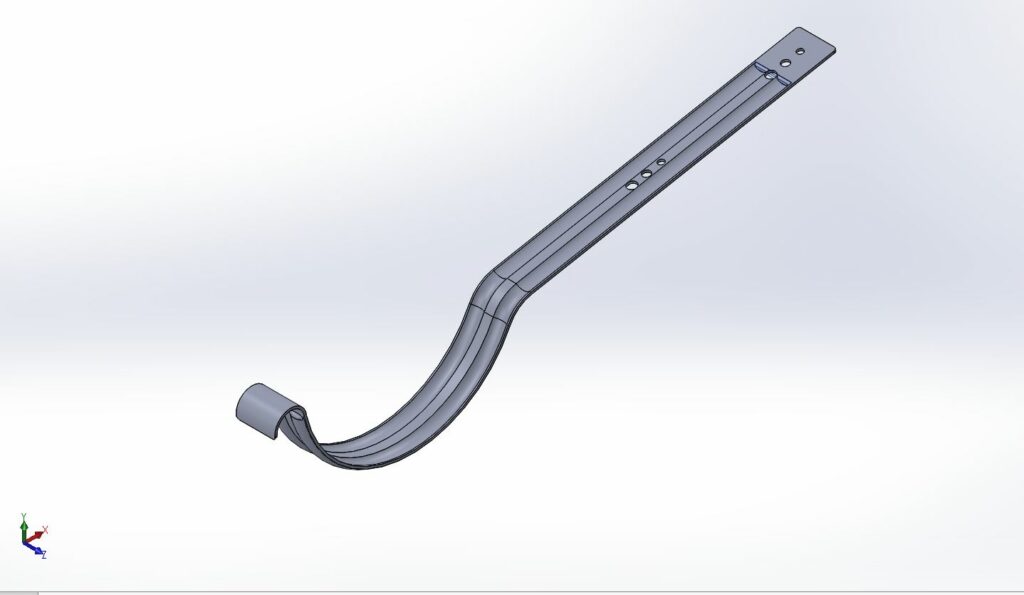

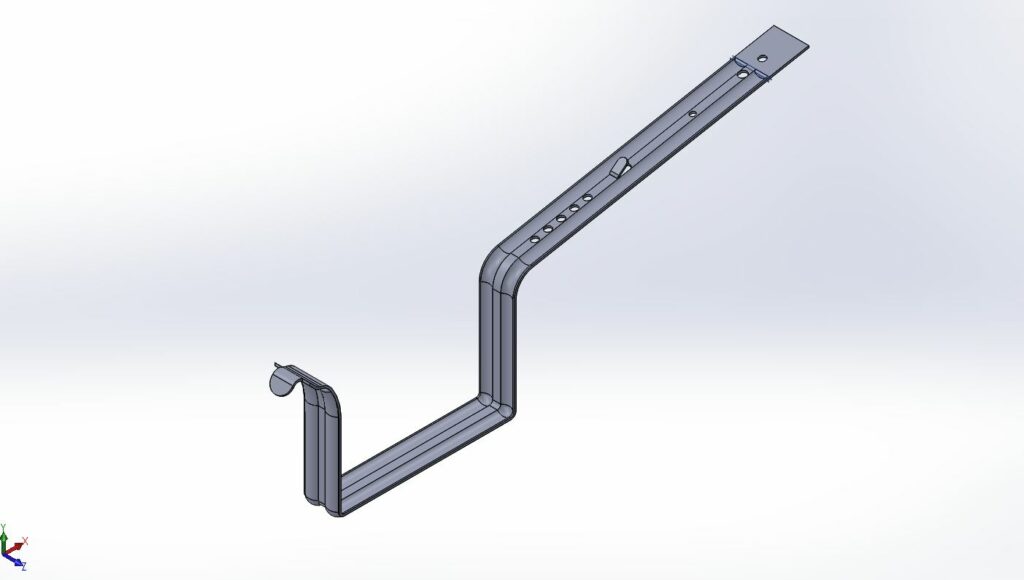

Produzione automatizzata di sostegni e tiranti per grondaie: efficienza e versatilità

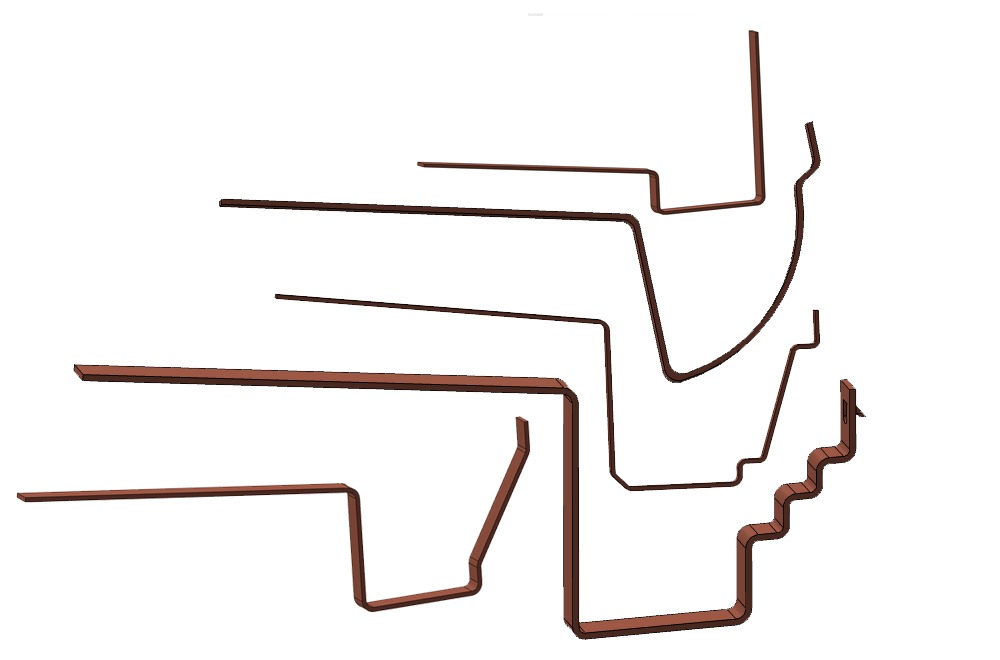

La macchina OPM SUPPORT LINE è la soluzione ideale per la produzione di sostegni e tiranti per grondaie, garantendo efficienza e versatilità. Può lavorare materiali come zincato, preverniciato, alluminio, rame e inox, con una produttività di circa 5/6 pezzi al minuto. Grazie agli stampi intercambiabili, è possibile ottenere una vasta gamma di forme e configurazioni, adattabili alle esigenze specifiche. La gestione delle diverse tipologie di fori avviene tramite il cambio stampo, mentre le unità possono essere traslate per una lavorazione su misura.

Conforme alle normative CE, la macchina include componenti avanzati: una centrale oleodinamica, un quadro elettrico, un avanzatore elettronico, unità dedicate a nervatura, taglio, foratura e formatura, un nastro espulsore e un PLC con software dedicato per il controllo e l’ottimizzazione della produzione.

Processo produttivo ottimizzato della macchina per sostegni e tiranti per grondaie

Il ciclo inizia con il caricamento del coil su uno svolgitore motorizzato. Il nastro passa poi attraverso un avanzatore elettronico/raddrizzatore per garantire precisione nella lavorazione. Il processo, completamente automatizzato, è gestito dal PLC, che controlla operazioni come nervatura, taglio, formatura e perforazione, fino al trasporto finale del prodotto tramite il nastro espulsore.

Gestione centralizzata e manutenzione semplificata

Il quadro elettrico centralizza tutte le unità di controllo, semplificando la diagnostica e la manutenzione. Il PLC, cuore della macchina, consente di impostare le caratteristiche tecniche dei sostegni e tiranti per grondaie, monitorare la produzione in tempo reale (industria 4.0) e garantire la sicurezza grazie a sensori e sistemi di rilevamento.

Sicurezza e affidabilità

Dotata di sistemi di sicurezza attiva e passiva, la macchina protegge l’operatore e l’impianto durante ogni fase del lavoro. Sensori e fotocellule monitorano costantemente il processo, interrompendo l’attività in caso di anomalie. Grazie alla certificazione CE, la macchina offre non solo efficienza, ma anche conformità alle normative italiane ed europee.

Con lo svolgitore motorizzato, con capacità di carico fino a 0,5 tonnellate e regolazione tramite inverter, il sistema garantisce massima flessibilità e protezione contro eventuali anomalie.

La macchina OPM SUPPORT LINE è la scelta ideale per chi cerca un impianto altamente performante per la produzione di sostegni e tiranti per grondaie, combinando precisione, sicurezza e innovazione.

Iscriviti al Nostro Canale YouTube per non perdere gli aggiornamenti sulle nuove macchine!