Learn how drywall constructions and profiling machines transform the construction industry

Drywall profiles play a vital role in construction and renovation projects. They provide strength, precision, and versatility for walls, ceilings, and partitions. These metal components, created using advanced technologies like the drywall profiling machine, ensure quick and professional results.

Types of drywall profiles and their applications

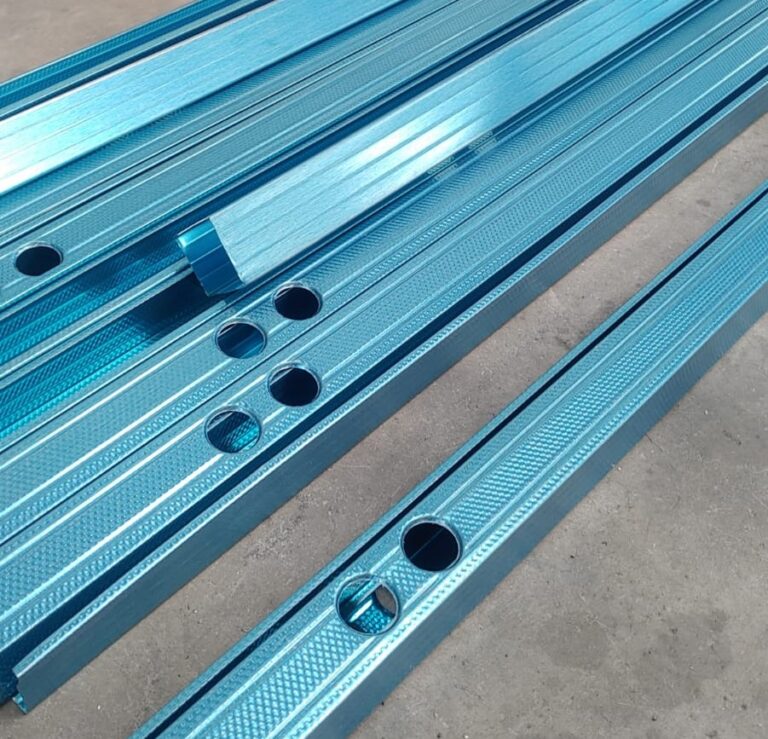

Drywall profiles come in different types, each designed for a specific purpose:

- UD Profile: Serves as a guide for CD profiles. It works well for supporting ceiling and cladding structures. This profile attaches directly to ceilings or walls.

- CD Profile: Acts as a load-bearing element for ceilings and walls. It slots into UD profiles and supports drywall panels securely.

- CW Profile: Stabilizes partition walls and improves sound insulation. Its design easily accommodates cables and piping.

- Omega Profile: Fastens drywall panels directly. It is favored for its simplicity and versatility in wall cladding projects.

With their modularity and lightweight nature, drywall profiles enable fast, clean construction. This approach reduces work time while ensuring a top-quality finish.

Why drywall constructions are so advantageous

Drywall is increasingly preferred in the construction industry due to its numerous advantages:

Lightweight and practical: Easy to transport and install, drywall suits renovations and new builds alike.

Quick to install: Building with drywall is significantly faster than traditional methods.

Provides insulation: The material’s properties, combined with insulating panels, enhance thermal and acoustic performance.

Highly versatile: Custom designs like curved walls, decorative ceilings, or niches are easily achieved.

Eco-friendly: Many drywall types use recycled materials, minimizing environmental impact.

Smooth finish: Drywall creates surfaces ready for painting or decorative plaster, delivering a flawless result.

Choosing between drywall and plaster

Your choice depends on the project’s needs:

Drywall: Best for lightweight, quick, and flexible designs. It’s ideal for partitions, ceilings, or claddings requiring modular solutions. Drywall also offers superior insulation and makes integrating cables and systems simple.

Plaster: Better suited for durable and robust surfaces like load-bearing or exterior walls. It provides a solid finish, perfect for high-impact or moisture-prone areas. However, plaster takes more time to apply and dry compared to drywall.

In summary, drywall works best for modern, fast, and adaptable projects, while plaster is the traditional choice for durability and strength.

Benefits of using of a drywall roll forming machine

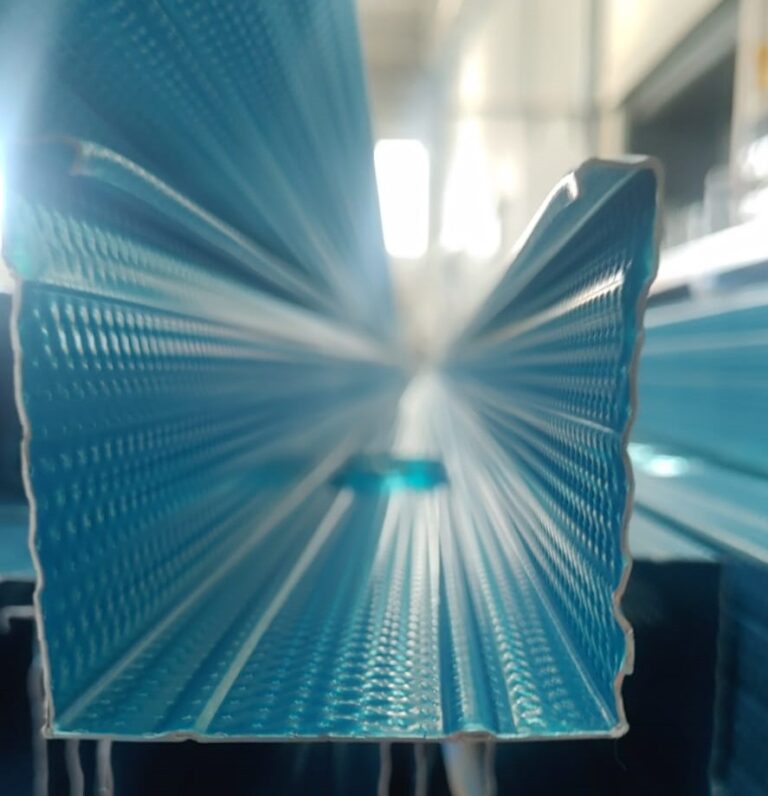

The OPM drywall profiling machine is versatile and allows the production of the full range of drywall profiles.

Producing drywall profiles requires precision and speed, characteristics ensured by using a drywall roll forming machine. Here are the main advantages of this technology:

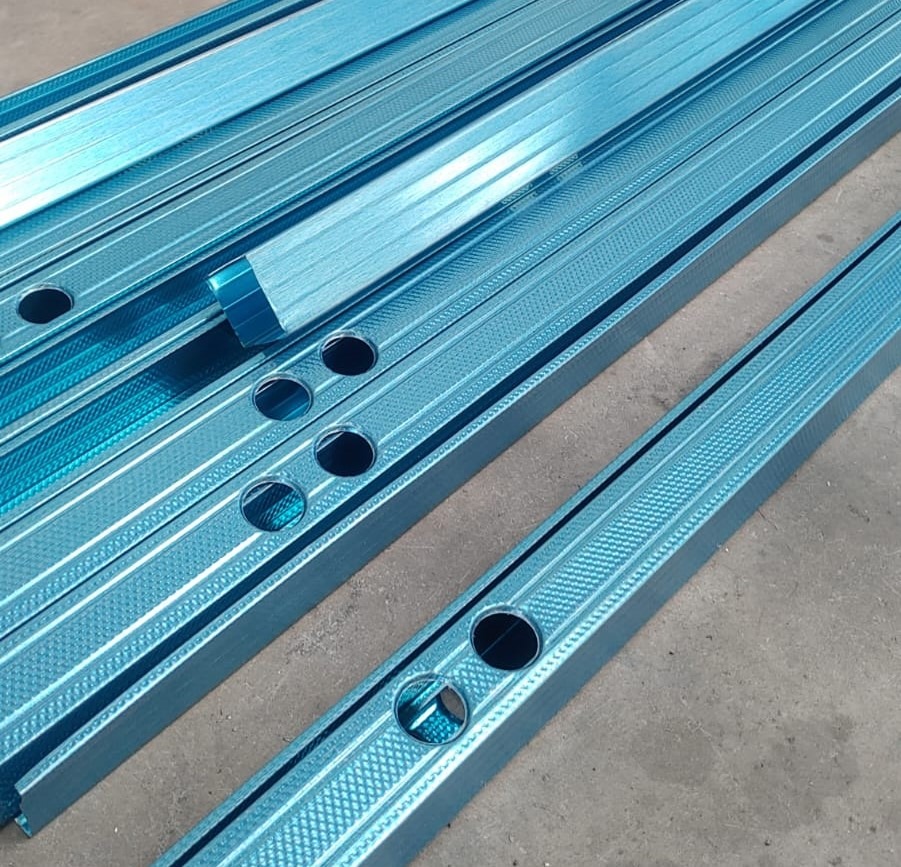

Custom profiles: Machines create tailored designs to match specific project needs.

Increased productivity: Automation ensures continuous, high-speed production, saving time and costs.

High precision: Profiles meet tight tolerances, ensuring easy assembly and stable structures.

Flexibility: These machines produce various profile types, including UD, CD, CW, and Omega, catering to diverse applications.

Why choose the drywall roll forming machine from OPM Stampi

The OPM Stampi drywall profiling machine (video) offers a state-of-the-art solution for creating metal profiles. With advanced technology and meticulous design, it ensures:

Reliability and durability: Built with high-quality materials and robust engineering.

Production flexibility: Adapts quickly to create different profile types.

Excellent support: Includes technical assistance and after-sales service for long-term value.

Investing in a roll forming profiling machine helps meet the demands of a dynamic market. Modern technology and efficient processes enable the creation of high-quality structures, boosting your competitive edge.